Sensors for Tako

Tako IIoT system is sensor agnostic and compatible with with any industrial sensor. Configured to work out of the box with any 4-20mA sensor, you can also add a signal conditioner to use other industrial sensors including digital sensors, 0-10V, 0-5V and others.

Sensor Kits

For your convenience we have assembled collections of the sensors we recommend for various industrial assets.

Typical dry vacuum pumps used in semiconductor manufacturing monitored with Tako Smart Device and 4-20mA sensors.

Recommended sensor kit for a dry vacuum pump system including 4-20mA sensors for Amperage (Dry Pump & Blower), Temperature (Dry Pump & Blower), Vibration (Dry Pump & Blower), and Pressure (Exhaust)

A Sensor for Every Application

Current

Flow

PH

Wind Speed

Temperature

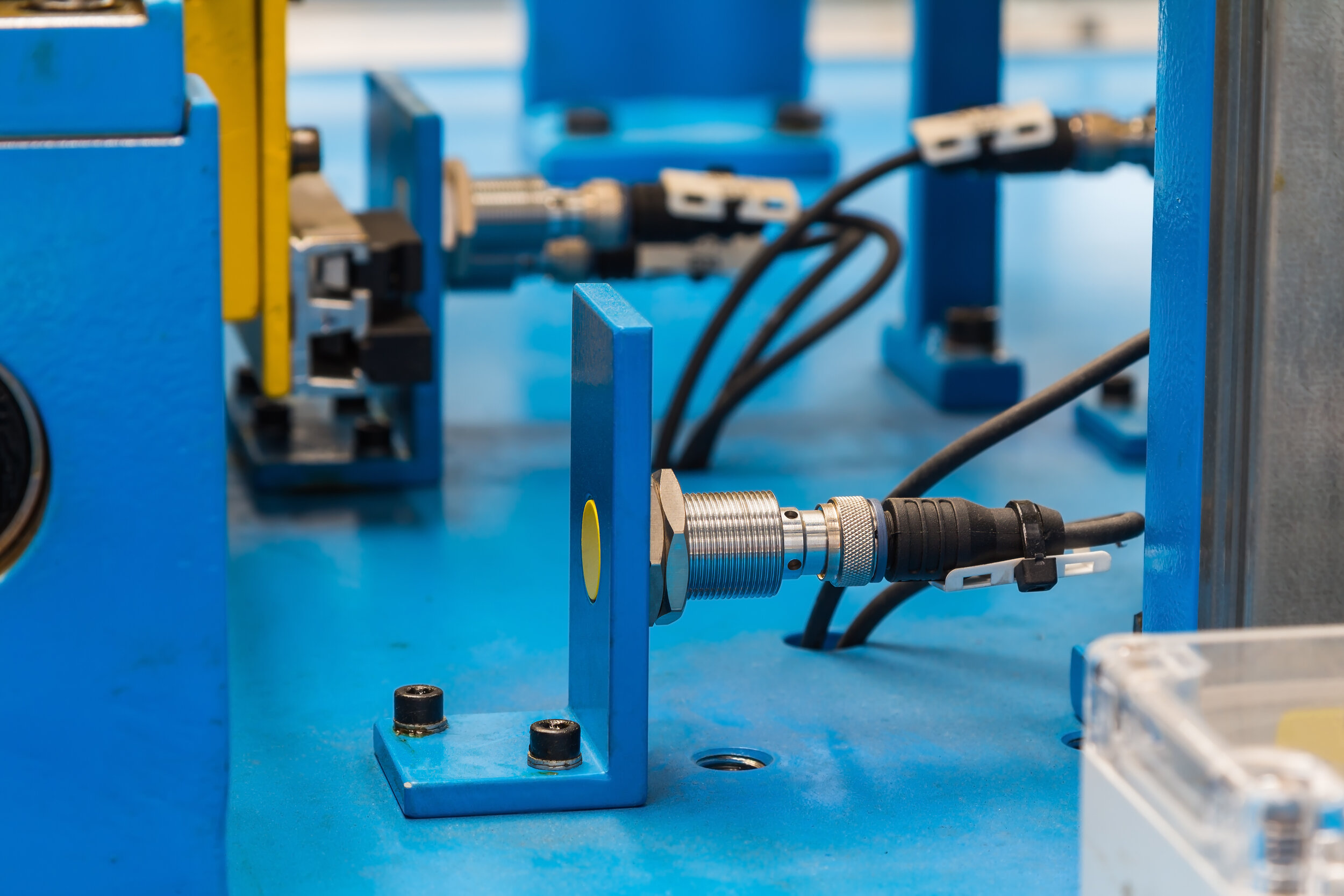

Proximity

Dissolved O2

Soil Moisture

Vibration

Noise

Water Level

Humidity

Pressure

Torque

Voltage

Carbon Monoxide

Other Sensors

Tako maintains a list of recommended sensors that we have tested and certified to meet our quality standards. For recommendations or questions regarding your existing sensors please contact us.

Criteria For Our Recommended Sensors

Build quality.

We want to make sure every piece of equipment we source and produce can stand up to the rigors of use. Because of this, we only employ the best of every kind of sensor we can find. Our typical quality assurance process goes through three major steps:

Review of the producing company

Stress-testing of specific sensor model in anticipated use environments

Accuracy testing

If a sensor is able to pass all three of these parameters, then it is registered as a qualified sensor and integrated into the stream of sellable items.

Practicality.

The primary question to answer here is Is this sensor useful? We try to curate a list of sensors that individuals and organizations want to use, not just sensors that are easy to introduce into the sales stream. By prioritizing usability, we are able to get more sensors into the hands of users at a more rapid pace than if we were to qualify any single sensor that comes across the desk at any given time. That being said, please contact us via the contact page if you have a sensor that you or your organization would find useful—we’re always happy to qualify the kind of sensor that is requested rather than following trends.

Ease of use.

How simple is it to use the sensor in question? We try to utilize sensors that have the same mentality we do—why make things hard when they can be easy? When things are easy to use, they get used. We want the sensors you need to get used.

Variety.

While we’re careful about what we choose to sell, we try to get as wide a variety of sensors as possible. In this way, we can make sure that we’re meeting the needs of as many people as possible, regardless of industry.

OEM Integrations

Original equipment manufacturers are encouraged to take advantage of the Tako system’s versatility and add remote monitoring capabilities by integrating with their industrial products. Original sensors can interface with Tako via RS-232 and other common connectors.

Please contact us to learn more.