Tako Software

Be everywhere at once with a digital view of your entire operation.

The Tako IIoT system includes cloud-based software making all your data available via the browser. Easy to customize settings enable you and your team to get the most out of alerts, machine health history, and asset management tools.

Features & Benefits

Machine Health and Alerts

0-10 Health Score.

Easy to read normalized data.

You set the expected sensor ranges for normal operation and Tako provides you with an easy to read health score from 0 to 10.

The health score is applied to each individual sensor, collections of sensors that make up an asset, and the combination of assets that make up an operation.

This way you can view the health of your entire system and quickly dial down to the root cause of any abnormal conditions.

Machine Health Alerts.

Stop problems before they happen.

Establish performance thresholds for your asset and be notified immediately via SMS and email when conditions are met or exceeded.

Trend Analysis

Use historical graphs to understand performance over time.

With historical graphs you are able to visualize and identify performance trends in your everyday operations. Utilize trends in data to identify thresholds for conditional and predictive maintenance.

A semiconductor manufacturing operation leveraged historical graphs to identify a vacuum pump exhaust clogging issues that occurred regularly every 4 months. Based on this data, the user was able to quickly identify the root cause and remedy the situation by introducing nitrogen into the exhaust. This extended the servicing to once every 10 months while increasing overall pump performance and longevity.

Investigate abnormalities in patterns.

With historical graphs you are able to visualize and identify performance trends in your everyday operations and investigate unexpected events. Utilize trend analysis to determine optimal thresholds for conditional maintenance.

Within days of installing the Tako system a prominent semiconductor manufacturer was able to identify the root cause of a “walking wafer” problem. They were having a loss of product issue due to silicone wafers randomly ‘walking’ off of their pedestal during production. Within a few production cycles, it was identified that the excessive vibration was in correlation to the air-cooling blower situated on the tool. The issue was easily remedied by installing proper isolation pads to the blower.

Optimize Maintenance

The precision needed for condition based maintenance (CBM).

Move from scheduled-based maintenance to optimal condition-based maintenance. The benefits of maintaining your machines based on condition include extending the total useful life, reduces total maintenance cost, and reduces unplanned downtime.

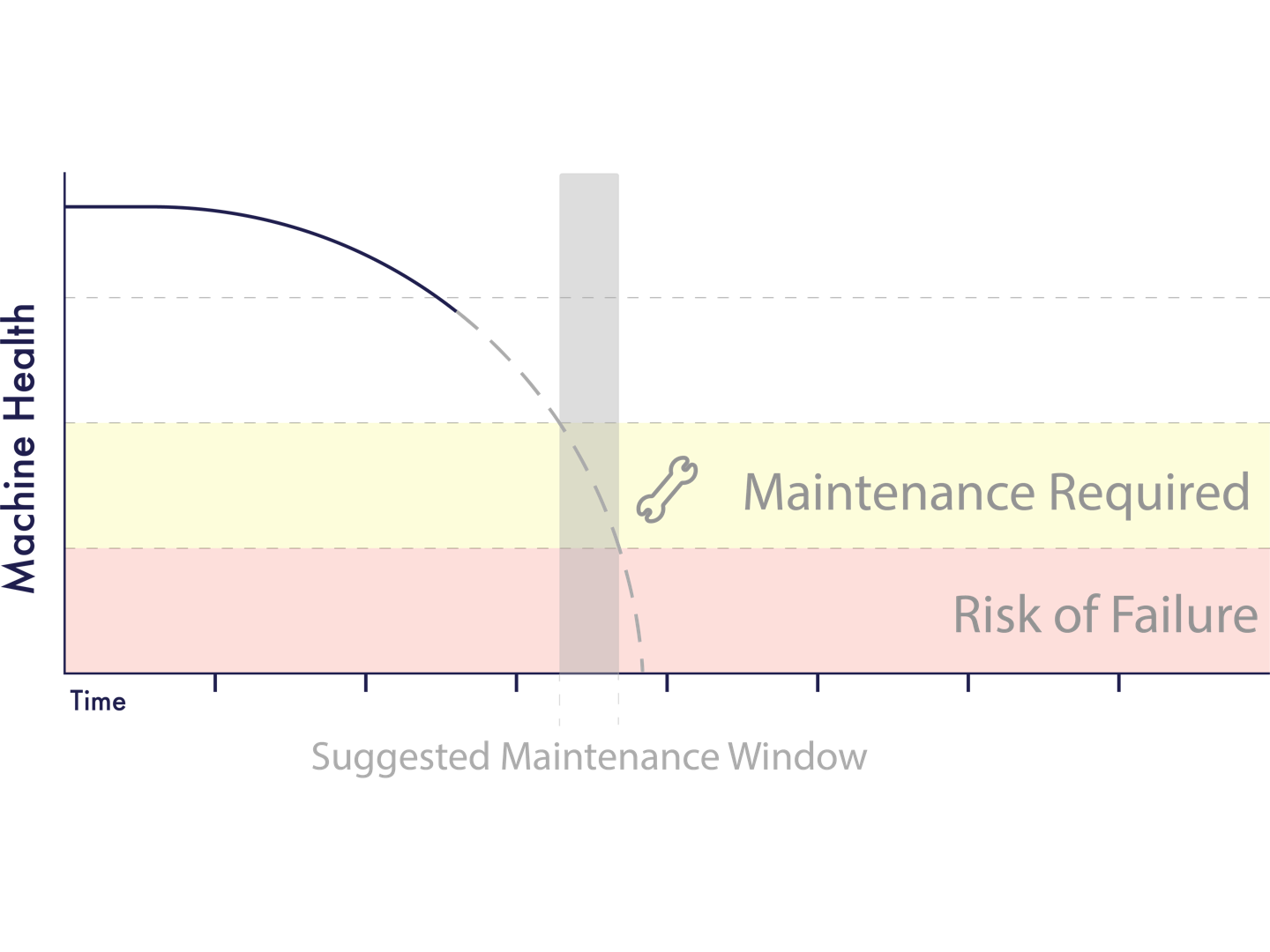

Predictive maintenance (PdM) identifies optimal repair windows.

The Tako application uses historical trends to predict when machine health will reach predetermined conditions for maintenance.

By predicting maintenance windows, asset management professionals can factor scheduled downtime and remaining-useful-life (RUL) into maintenance programs.

Prescriptive maintenance (PxM) supported by deep industry knowledge.

Once a problem is identified, prescriptive maintenance (PxM) helps quickly prescribe the solution.

By recognizing patterns from historical data, the Tako system correlates current conditions with likely causes and identifies the most probable remedies.

In the event that conditions can not be correlated to the root cause, Tako users can grant data access to their trusted maintenance and repair providers. Tako users can also tap into our network of data experts and asset management professionals. Think of it as tele-health for your machines.

Asset Management

Assign maintenance requests directly from the app.

While viewing the condition of your asset you can take action and assign tasks at the click of a button.

Whether your service team is in house or an offsite contractor you have the ability to send a service request with all of your asset’s pertinent information attached.

Track maintenance updates via kanban workflows.

A simple yet powerful ticketing system to assign task and manage to completion.

Eyes on your offsite assets with geolocation.

With a connected gateway in the service room, your assets will continue to report status and location.

Repair shops can now automatically report equipment status and when it has been restored to original operating condition. Asset managers can now track equipment location and account for all assets currently in use and offsite in repair.